RECÉPIEUX® PROCESS : HOW DOES IT WORK ?

RECÉPIEUX® is the only process in the world compatible with the demanding requirements of HQE sites (French standard for green building) and potentially dangerous (European SEVESO Directive 82/501/EC).

Pre-recépage consists of introducing in fresh concrete a kit made up of :

Polyethylene foams, of different colours and diameters, to isolate the steels

One or more plastic single-use special flask (“breakers” with a specific “UFO” design) with PVC tubes attached

An expanding mortar

Once the kit has been introduced into the concrete pile at the correct height, we wait at least 3 days so that the concrete is sufficiently hard (there is no maximum timeframe).

The breakers are then filled with expanding mortar, which creates a vertical traction force of roughly 40 tonnes per breaker over the following hours.

A perfectly clean and horizontal crack cuts the pile and the surplus concrete can be removed from the rest of the pile without impact or vibration. The recépage precision is to the nearest centimetre.

THE ADVANTAGES

The only technique in the world approved by CETE in Lyon (authorized by French Ministry of Ecology, Sustainable Development and Energy) to be used sooner than the usual 7-day minimum (when this is respected) !

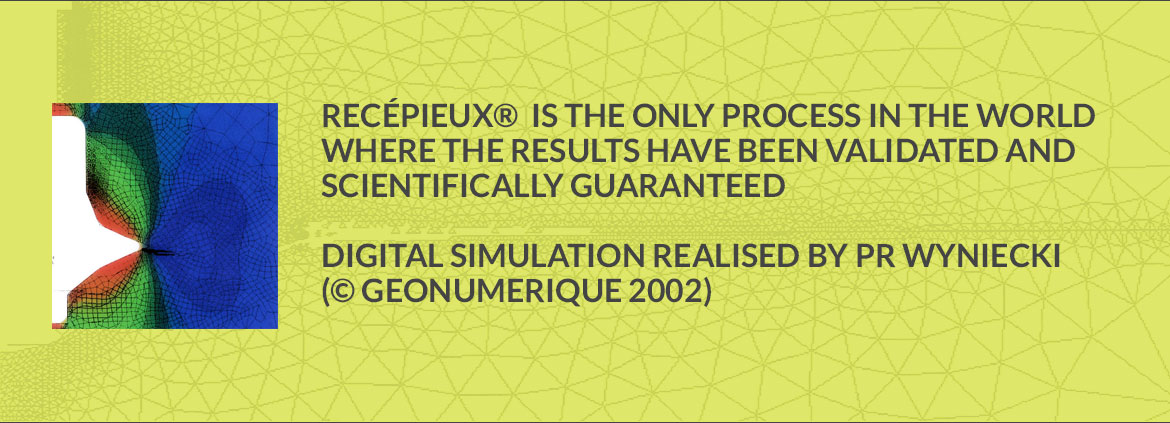

No cracking below the cut-off level : this has been validated by digital simulation.

Savings in time and work: can be counted in weeks! The removal of the surplus concrete can be done at the same time as the levelling work (3 times quicker). When the kit is pre-fixed to the reinforcing cage the labour cost becomes negligible.

Clean site: the integrity of the steel reinforcement is maintained, the pile head is clean and flat, the surface remains undamaged, no need for additional finishing, no need for heavy machines or equipment.

Costs are controlled: the price of the kit varies according to the diameter of the pile and is little affected by the height of trimming. Labour costs are low and easily controlled. Each day saved on site reduces the fixed costs of the whole project.

An ecological and pain-free process: no impacts, noise or vibration. No dust or CO2. Hardship for workers is practically reduced to zero (compared to all other solutions).

The Recépieux® METHOD IN 4 STEPS :

1 - PREPARATION BEFORE PUMPING

• Installing the polyethylene foams.

• Attaching the breakers to the PVC tube.

2 - POSITIONING THE BREAKERS

Breakers are fixed to the reinforcing cage or pushed into the concrete after pouring.

3 - INSTALLING THE EXPANDING AGENT

Wait a minimum of 3 days for the concrete to harden, you do not have a maximum.

4 - REMOVING THE BLOCK

Uncover the pile head during earthwork before lifting off the concrete block vertically (to avoid bending the steels).

FINAL RESULT